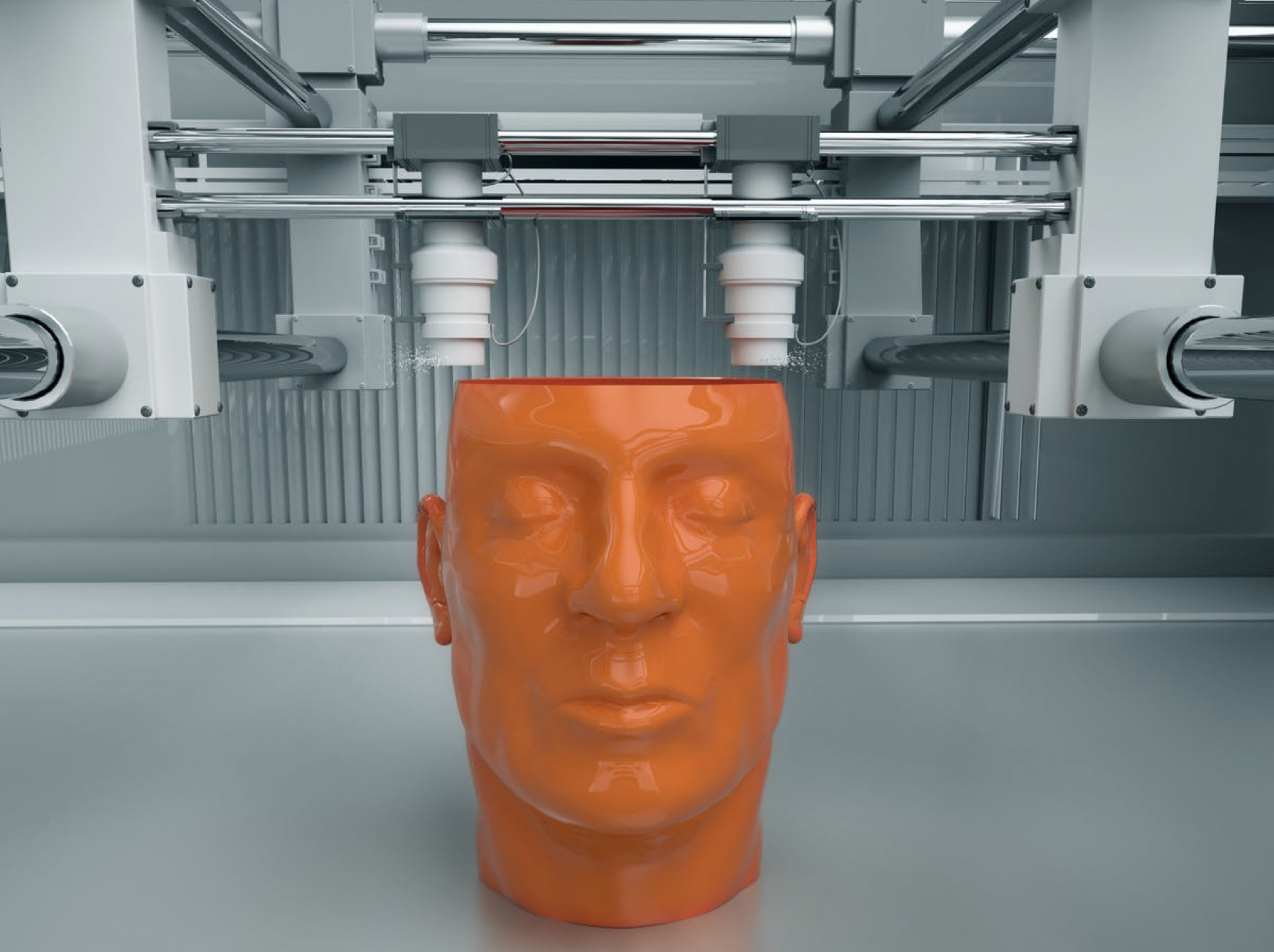

Because much of the drug market involves making medications on a massive scale, the concept of customization, though present, is seen as limited. As a result, this research group

Using the patient’s weight, age and other pertinent factors, the research group has developed an algorithm to make a 3d model for a tablet catered to the patient.

One of the challenges facing the CBD industry is the challenge of providing consistent and accurate measurements of pertinent ingredients. For example, federally legal CBD oil must contain no more than .3% THC. You might see a packet of lotion that says 1000mg of CBD on the label. Yet it might surprise you that the actual measurement could be 984mg.

When talking about today’s pharmaceutical market, measured ingredients rarely deviate to this extent from the labeled amounts. Nevertheless, CBD, hemp, and cannabis products are all mainly derived from one source. This source is a plant that does not want to be controlled. Even with the best of farming practices, the unpredictable can occur. The current state of this newly formed industry has lead to a temporary “acceptance” that 1000mg could actually be 984mg. A 10-20% shift between what’s on the label and what’s in the product is not unfathomable.

While the potential is promising, members of the research group acknowledge that more needs to be done. One area of improvement is the need for a more detailed algorithm; specifically more parameters about the patients condition. However, in the age of cyberattacks, many are concerned about the negative impact of more patient information on the internet.

There has already been progress in 3d printing in the mainstream pharmaceutical market. Opiod tablets have been made with properties that inhibit addiction. While more research must take place, scientists are hopeful that a new drug can be developed to combat the oppiod crisis. There have also been attempts to combine multiple prescriptions into one pill.